There is a common misconception among people that PCB design and hardware design are the same. However, for PCB design engineers, they are different in multiple ways. Hardware and PCB design are fundamental processes in developing electronic products and play a crucial role in the functionality and reliability of devices. They differ in various aspects, such as skill requirements, scope, abstraction levels, design processes, and tools used.

A PCB design engineer needs to understand the difference between PCB and hardware design for successful product development and efficient collaboration between design teams.

Hardware Design

Hardware design is a critical process to create and develop the physical component of electronic systems. During the design process, a hardware design solution provider selects the appropriate components, such as sensors, memory, microprocessor, etc., to interconnect them for intended functionality.

PCB Design

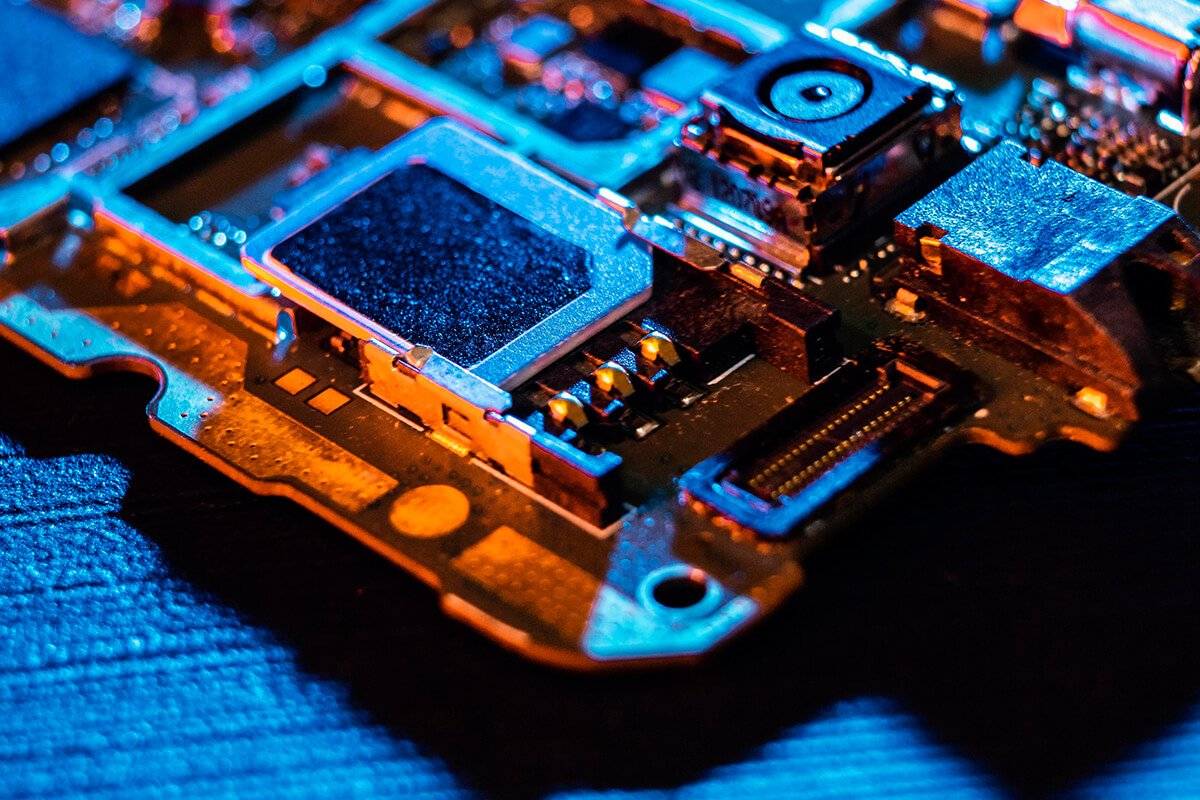

PCB design, or hardware board design, is a subset of hardware design that translates the schematic diagram into a physical layout on a printed circuit board. The PCB offers a platform for mounting and interconnecting electronic components to create a functioning system. Moreover, some examples of PCB design software tools include Allegro, Xpedition, Altium, KiCAD etc.

Critical Differences Between Hardware Design and PCB Design

Focus and Goals

PCB Design: PCB design focuses on creating the layout for the interconnection of electronic components on PCB. It allows companies to optimize the placement of electronic components, power distribution, and routing of signal traces to ensure the device’s functioning. PCB designing translates the hardware design into a physical PCB design layout, meeting electrical and mechanical constraints while considering thermal management, manufacturability, and signal integrity.

Hardware Design: Hardware design helps companies to conceptualize and define the overall architecture of the electronic system for better functionality. It aids in selecting the appropriate components for better system behavior and establishes the interaction between different hardware modules, meeting device functional requirements. With the help of hardware design, companies can create a comprehensive electronic system according to their specific needs, such as size, power, cost, and performance.

Skill Sets and Expertise Requirement

PCB Design: To create a PCB layout and ensure proper functionality and manufacturability, a PCB design engineer must understand electronics. They should know various PCB design software, as companies use different software according to their specific needs. PCB designers must understand PCB and its manufacturing process and concepts like thermal considerations, impedance matching, Signal and Power integrity, and EMI/EMC mitigation techniques. It is also essential to have a deep knowledge of PCB design rules and guidelines for different circuits such as Analog, Digital, RF and Power supply.

Hardware Design: On the other hand, a hardware designer must have a broad understanding of electronics to conceptualize, create, and refine the architecture of the electronic device. They must also be well-trained in design principles to optimize and analyze the complex electronics system. Apart from this, they must be proficient in programming languages.

Design Tools and Software

PCB Design: To create a reliable, efficient, and cost-effective board design, a PCB design engineer must have a thorough knowledge of PCB design software and tools. It helps designers create the PCBs’ physical layout, manage design constraints, place components, route traces and deliver Manufacturing files.

Hardware Design: To work on hardware design, hardware designers must understand various tools to create electronic circuit diagrams.

Collaboration Between Hardware and PCB Designers

For a successful design, both PCB design engineers and hardware designers must be on the same page. They should collaborate from the initial stage to define the project’s requirements, goals, and constraints. The communication between them helps solve the constraints, such as the size of the hardware board design, thermal consideration, power requirements, and any specific guidelines. Moreover, they must provide regular feedback to improve the final design.

Also Know: 5G IoT & How It Is Significant for the Future of Connected Vehicles

Concluding Remarks

In a nutshell, understanding the clear difference between hardware and PCB design helps in creating successful electronic products. It becomes even more critical as the need for compact electronic products has increased, making the structure complex. That’s where Tessolve comes in with years of experience. We offer hardware solutions in multiple segments. At Tessolve, we offer quality PCB design services, including PCB layouts, schematic capture, package engineering, mechanical engineering, etc.

Get in touch with us and get the right hardware design solution!