An absolute commitment in every engineered piece

Our Focus

Quality – integrated into every project we deliver

“At Tessolve, our mission is to deliver high quality, value adds engineering solutions and products to our customers. Our Quality processes are world class and closely integrated with Project delivery and not treated as an afterthought. We continuously invest in upgrading and automating our Quality systems to ensure zero defects and exceed customer expectations!”

Srini Chinamilli, CEO, Tessolve

Quality Policy

Staying true to first-pass product delivery

We are committed to meeting and exceeding customer expectations by delivering quality solutions and customer service. We strive hard to continually improve the quality of services through skill upgrades and teamwork.

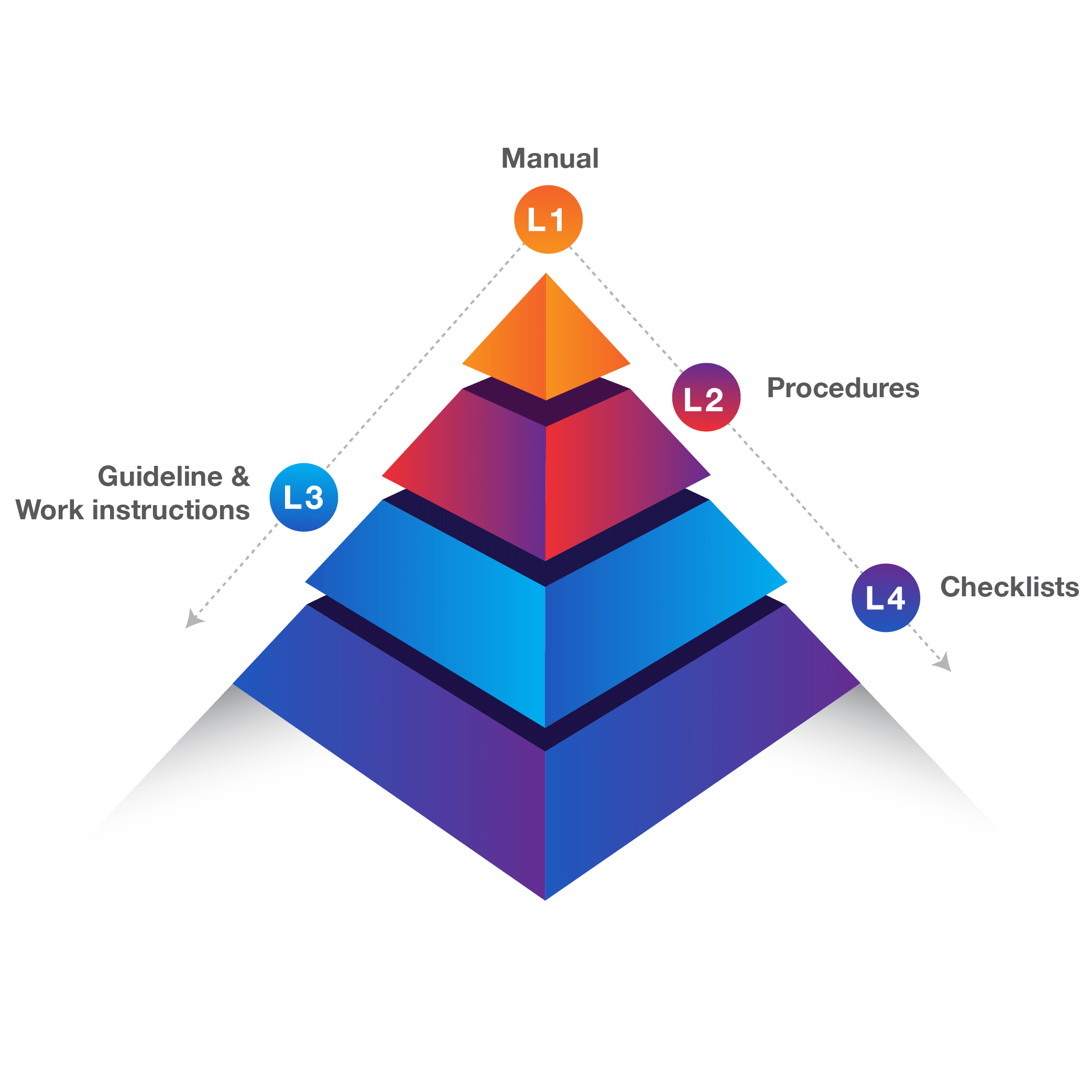

Our Quality Pyramid

Efficient quality management system –

Comprises a four-level system. All our departments are governed by a set of Procedures, Processes based on the system, with each parameter meticulously followed by all employees in the organization.

Our Quality Manual

Written to adhere to the International Organization for Standardization requirements, our quality manual is a well-documented representation of Procedures, Guidelines, Instructions, and Checklists, drafted to meet customer expectations.

Our process & checklist are prepared on 100 person-hours of invaluable practical experiences of our project team. We update the process & Checklists at regular intervals for continuous improvement.

The Process We Follow

Benchmarking deliverables at every stage

- QMS system complying with ISO9001 followed in the organization since 2004

- Regular Coordination with Internal & External Suppliers by the project team to provide quality-assured output within a stipulated time

- Process tracking & monitoring by internally developed tools

- Defined Quality stages & checks by dedicated QA Personnel to ensure Quality output to the customer

- Committed to Continuous improvement through training & Knowledge update

- Structured 8D process followed for handling Customer complaints

- The FMEA process followed based on customer requirements & automotive projects

- EN9100 standard tracked for Aerospace projects

- NABL-accredited Reliability laboratory

- Net promoter score (NPS) followed for measuring customer satisfaction

- An active member of IPC, the Industry adopted standard for PCB

Certifications

Instances of our recognized quality practice

ISO9001:2015 (Bengaluru – Electronic City Site)

Certificate PDF Download

ISO9001:2015

(US – Austin Site)

Certificate PDF Download

ISO/IEC 17025:2017 Certification – NABL Accreditation with Scope

Certificate PDF Download

With Every Delivery

Quality is assured by the Tessolve team

Our team of Quality Professionals verifies the deliverables against the standard checklist at various stages to ensure that deliverables meet our benchmarks and customer specifications. They act as customers confirming that deliverables are quality assured with our set procedures and checklists, helping assess all critical aspects of project benchmarking.